By providing visual feedback of monthly water use, staff were empowered to make changes.

Using data from their Integrated Resource Assessment, staff saw the potential water savings available from a new barrel washing system. Their decision to invest in a new system paid off with substantial water savings.

In the production facility, water use is monitored throughout, allowing for continuous improvement.

Simple Steps to Reduce Winery Water Use

As one of the original members of both the Napa Green Certified Land and Winery programs, St. Supéry Estate Vineyards & Winery recognizes that sustainability is a path, not a destination. One of their key discoveries on the path to improvement is that day-to-day awareness and staff empowerment are critical.

In 2016, as part of St. Supéry’s Napa Green Winery re-certification process they participated in their first “Integrated Resource Assessment.” The assessment is a one-stop energy, water and waste audit that establishes baselines for energy and water use and waste diversion to evaluate areas for improvement.

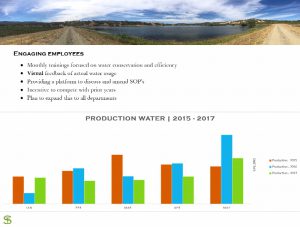

After reviewing their initial water data, the staff at St. Supéry decided to focus on their water intensity metric. As a first step they trended the water data over time beginning in 2015 to show changes seasonally and with different operations.

Converting numbers to graphs is a key tool in communicating water use, showing large variances and inconsistencies.

- David Hiestand, Production Coordinator

By tracking use on days with different water intensive activities like bottling, tank and barrel cleaning, we can really see the difference. There are surprises, like the bottling line using more than we thought. We're now looking at steam and other cleaning alternatives.

- Brooke Shenk, Winemaker

Engaging staff and sharing ongoing accomplishments paid off. In 2016, St. Supéry achieved a 33 percent decrease in production water use over 2015, and in the first half of 2017, they achieved an additional 22 percent decrease over the same period in 2016.

Empowered by their successful efficiency efforts, St. Supéry is now baselining water use per guest and engaging the hospitality team in a little friendly competition. While water use efficiency is only one element of participation in Napa Green, St. Supéry has shown the rewards available to all participants by using focused metrics and getting your team on board to achieve shared goals.

Making the commitment to third party certification takes time and effort, but it is worth it to demonstrate our commitment to the community and to protect our watershed, our land and the air we breathe.

- Susan Boswell, Chateau Boswell Winery