A panel of four experts highlighted some of the hottest topics in energy conservation and carbon emission reductions in St. Helena at a Napa Green event held June 9. The panelists recommended taking specific actions to address climate change–adopting LEDs, rightsizing solar energy, buying EV’s, reducing fleet and warehouse emissions and more.

Those big sheets of plastic shrinkwrap found in distribution warehouses could have a second life instead of going to landfills, if Southern Glazer’s new sustainability program adopts an employee’s suggestion that the company rated #1 in a recent internal sustainability idea competition. The $21 billion distribution giant is evaluating working with plastics recycling giant Trex to recycle the wrap and other plastics. That’s according to Cindy Leonard, Executive Vice President, Fine Wine Division, who laid out a partial preview of some of the company’s initial sustainability roadmap.

Chateau Montelena winemaker Matt Crafton is looking to a German company to supply lower cost solar arrays that could power the winery more efficiently. Many wineries need to ensure that PGE’s Power Safety Power Shutoffs don’t interrupt production, he said. “Most of us can put a dollar figure on what it costs when our winery shuts down. So think about that.”

Beer industry engineering veteran Bill Bennett, Napa Green’s winery project engineer since 2010, told wineries to take energy conservation measures seriously before scaling up a solar energy solution. “Don’t solarize inefficiency,” he said. He has conducted 160 winery evaluations, measuring baselines and progress.

Charlie Gregg, Head of Sales at Sausalito based American Solar said, “Friends say ‘Is it the right time for solar?’ Yes. 10 years ago. Seven years ago. Five years ago. And it’s still the right time. So my suggestion to you is get the efficiency piece right.”

“You all are the folks who can make a difference right now with what you do, by installing renewable energy systems–with solar as the most obvious and economically feasible.”

American Solar’s Commercial Development Manager Jason Nelson hammered home the point that flexible tax credits make solar investment extremely attractive.

But it was Leonard’s presentation that captured the most attention, due to the company’s size, breadth and pivotal role in emissions for alcoholic beverages.

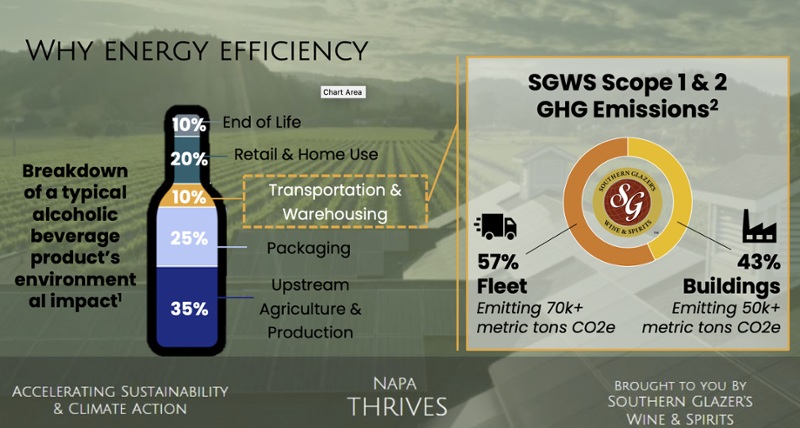

Leonard presented a graph showing that transportation and warehousing make up 10 percent of alcoholic beverage GHG emissions (based on work with Southern’s consultant Schneider Electric) for Scope 1 and 2 alone. (Scope 3 estimates are not yet available.)

An earlier study by the Wine Institute (based on 2011 data) put the transportation impact at 13 percent of Scope 1 and 2.

Breaking down the 10 percent figure, Southern Glazer’s attributes 57 percent of its GHG emissions to its fleet, which it says emits 70k+ metric tons CO2 and 43 percent to its buildings which it says emit 50k+ metric tons of CO2.

“We are the largest wholesaler in the United States with over 14 million square feet of warehouse space.That is 320 acres. How we do business together matters,” she said. Seven percent of the company’s warehouse space is in Florida, she said, where Hurricane Ida destroyed facilities in 2017.

“We started this sustainability project in Q2 and the beginning of Q3. So we’re in the ideation phase of how we can best corporately address as well as work with the different states,” Leonard said.

“We would love to put solar on in Florida. We want to talk about opportunities and how we can store the wonderful Florida sunshine, Tesla batteries, or whatever we need to do, so that we can start improving our EV proposition with our forklifts, and all the machinery we can probably use solar energy with.”

She continued, “Here are areas that we’re focusing on: efficiencies in our warehouse–we’re moving to LED. All the plastic wrapping? We are right now working with Trex to recycle it. So it can be used a second time and a third time.”

“Arizona is working on EV right now,” she said, adding that Southern is also evaluating using smaller vehicles for delivery in refrigerated containers to on premise and independent retailers. After conducting an Arizona pilot with 2 Xos Class 7 trucks, in December Southern announced its purchase order for 10 Xos Class 7 refrigerated beverage trucks (which do not require drivers with commercial licenses) for use in Texas. “The big warehouses, grocery, Albertsons, all would still be serviced using the big trucks,” she said.

“We are looking at automatic shut offs, so if the truck has been idling for five minutes, they shut down,” she said. “We have monitors in the cab so we can take a look at what the temperature is from inside that cab all the time. So when your cellar creates this beautiful product, we are committed to making sure that it gets all the way to our warehouses at that same temperature with minimal variation.”

A baseline audit gave Southern insights into its biggest gaps, she said. ”We started with the current state…We were shocked to find out that 60 percent of our sites did not measure water usage. And 90 percent did not manage or take a look at what their waste output was. That changed four months ago.”

“Now the big, big thing for us is the Idea Distillery,” she said, a program that incorporates suggestions from the company’s 22,000 employees. “We got 3,000 presentations back like that. It was the quickest response we ever had.”

The company put out a press release in April showing the winning submissions.

The sales teams alone contributed 300 ideas, she said, one of which is being adopted, incentivizing sales reps to buy EVs. “Rather than paying for gasoline (which we do), we’re now working on a paycheck offset that will accumulate, and we will encourage you to go get an EV,” she said.

“So when our sales teams are driving around town, seeing our customers, they are now encouraged–we’re piloting this in Florida right now–to go get an EV. And maybe that three years worth of gas, we would have paid, will be a paycheck offset.

“We feel this is very important to take a leadership role. And as we pilot this, if it proves out, we will roll this out across all 35 markets. So this is super exciting.”

Another winning employee suggestion was adoption of waterless urinals. “We’re taking a look at our water usage…and waterless urinals. I don’t know how that works. I don’t want to know,” she joked, getting a laugh from the crowd, “but if it is something that is absolutely necessary, I’m all in.”

Repeating the theme of partnership and learning from each other articulated by panelists throughout the session, Leonard also said the company will be announcing its 2030 plans in the next 30-60 days. “We’re all in this together and we feel that. We want to be a good partner in this space. It’s so very important.”

As Crafton said, summing up the panel experts’ advice. “it’s really about the entire ecosystem, not just the vineyard, not just the winery. t’s in our packaging, it’s in the compost or above the ground, and everything in between.”